BPI-6202 Embedded single board industrial computer

Contents

- 1 Embedded industrial computer overview

- 2 BPI-6202 Embedded Single Board Industrial Computer

- 2.1 BPI-6202 PCBA design

- 2.2 BPI-6202 product

- 2.2.1 About BPI-6202 Product

- 2.2.2 BPI-6202 interface description

- 2.2.3 BPI-6202 product key feature

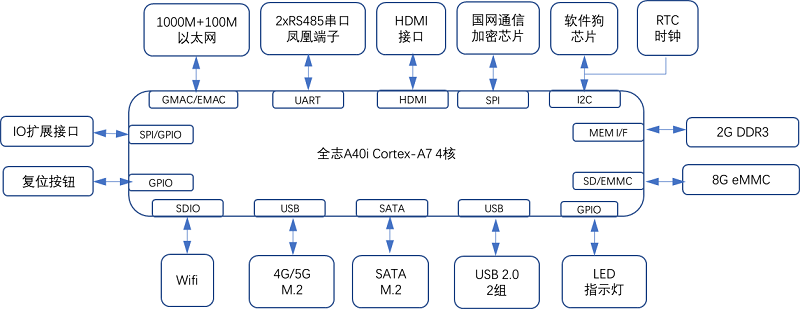

- 2.2.4 Internal logical structure

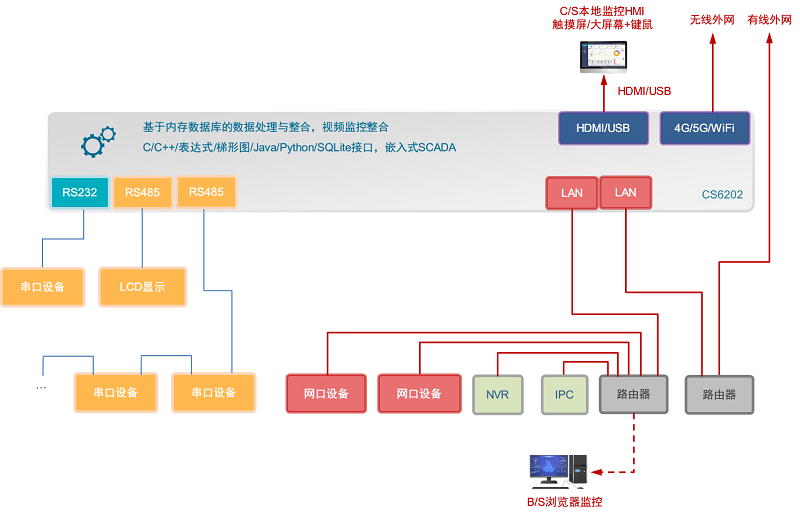

- 2.2.5 External connection

- 2.2.6 Technical Description

- 2.2.7 The main function

- 2.2.8 Technical specifications

- 2.2.9 Environmental Specifications

- 2.2.10 Physical Specifications

- 3 Source code

- 4 Resource

- 5 System Image

- 6 Cooperation method

- 7 Easy to buy sample

Embedded industrial computer overview

Definition and application scenarios of embedded industrial computer

Industrial Personal Computer (IPC for short) is a reinforced and enhanced microcomputer that appeared in the 1990s and is widely used in industrial field monitoring and control. Industrial personal computers often operate in harsh environments. Data security requirements are also higher, so industrial computers are usually specially designed for reinforcement, dust-proof, moisture-proof, corrosion-proof, radiation-proof, etc. Up to now, the X86+Windows (Wintel) architecture is still the mainstream solution for industrial computers. It can be defined as a traditional industrial computer. Generally speaking

While the traditional industrial computer plays an important role in the automation and informatization of the industrial control field, its inherent weakness has always plagued manufacturers, integrators and users. Everyone is looking for a better solution

In the past ten years, the embedded system has developed rapidly. With its low power consumption, low cost and continuously improved high performance, it has become the only solution for mobile devices (mobile phones, PADs); The ideal choice for data acquisition and processing in various industries. The embedded system of ARM architecture has the characteristics of flexible and efficient customization of software and hardware solutions. At present, a complete industrial chain ecosystem has been formed, which can provide users with solutions that meet their actual needs and have certain advances. Products with extended margins and more competitive prices; when user needs gradually exceed the capabilities of current products, they can continuously provide new products that meet user requirements through rapid program design and iteration, and can realize "needs— —Technology—Scheme—Product—Market—User—Demand” a virtuous circle of rising

Compared with the traditional industrial computer, the specially designed system based on the embedded computer architecture is called the embedded industrial computer.

The main features of traditional industrial computer and embedded industrial computer are compared as follows:

| Nomber | Key elements | Traditional industrial computer (Windows+X86) | Embedded industrial computer (Linux+LoongArch/ARM) |

| 1 | performance | Commercial-grade Celeron or commercial/industrial-grade Core i3~I5 | Industrial grade, higher performance than Celeron, weaker than I3 |

| 2 | safety | Vulnerable, vulnerable to viruses and hackers | Stable system, few upgrades, high security |

| 3 | real-time | Poor real-time responsiveness | Real-time responsiveness can meet the requirements |

| 4 | reliability | High power consumption requires strong heat dissipation and low reliability | Low power consumption does not need to consider heat dissipation, high reliability |

| 5 | Scalability | It is complicated to expand various interfaces on the motherboard | It is more convenient to expand various interfaces on the core board/development board |

| 6 | industrial grade | It is more difficult to realize real industrial grade products | It is easier to realize real industrial grade products |

| 7 | Customization | Customization efficiency is low and cost is high | Application-oriented fast and efficient customization and iteration |

| 8 | performance | Insufficient or excess performance for industrial applications | Application-specific solutions with the best performance |

| 9 | overall price | higher | Application-specific, price advantage |

| 10 | Operation and maintenance cost | High power consumption and high operation and maintenance costs | Low power consumption and low cost, green and environmental protection |

| 11 | life cycle | Frequent replacement, difficult to guarantee inventory | Long CPU life cycle, guaranteed inventory |

Embedded industrial computer has become a strong competitor of traditional industrial computer. In the future, the former will form an overwhelming advantage over the latter, there is no suspense

Application Scenarios of Embedded Industrial Computers

The rapid development of the industrial Internet and the Internet of Things is not only a battle for many computer software and hardware manufacturers (including communication solutions and product manufacturers, which are essentially computer systems, even embedded system software and hardware manufacturers) trying to enter the relatively high-profit industry. It is a successive attempt to monitor the industry market; it is also an enlightenment movement to open up "people's awareness of people's wisdom" and popularize professional knowledge. This big storm, which has lasted for more than ten years, has expanded the general public's demand and imagination for monitoring and control applications to every corner of all walks of life

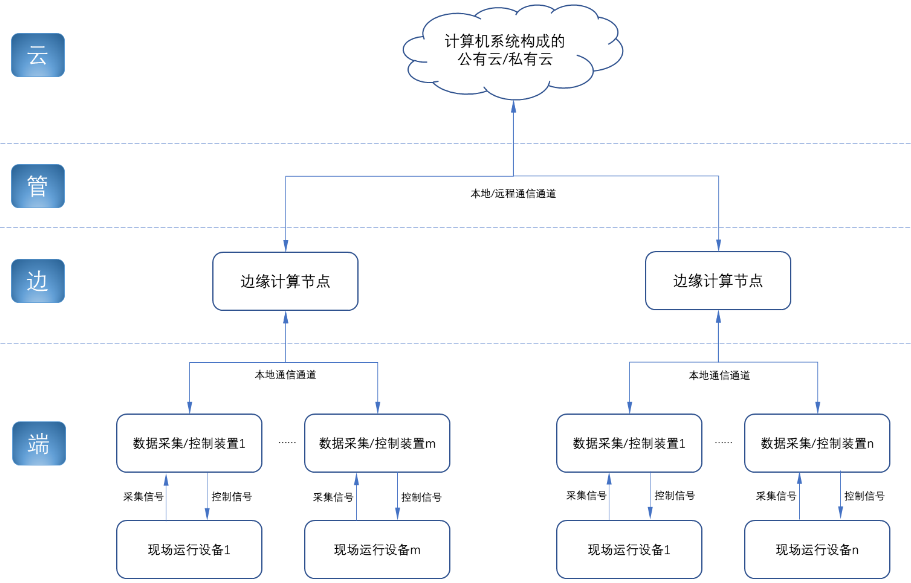

The concept of "cloud-pipe-edge-end" is a classic summary and induction of the principles of surveillance and control based on Internet thinking and terms; The mainstream model and architecture adopted by monitoring applications in various industries for decades

- Cloud: The computer system that implements the monitoring center system and more advanced application software and algorithms. The "cloud" here includes both the "public cloud" on the Internet and the "private cloud" on the enterprise LAN. Build "cloud" computer systems, currently mainly high-end X86+Windows/Linux servers, and their clusters

- Tube: Provide various efficient, reliable, convenient and cost-effective wired/wireless channels for both sides of the equipment. There are not only "pipes" between the "cloud" and "edge", such as wide area Ethernet, 4G/5G, etc.; between the "edge" and "end" of the application site, there are also pipes suitable for on-site application scenarios. The existence of wired/wireless "pipes", such as local Ethernet, serial port, high-speed power line carrier (HPLC), LoRa, ZigBee, WIFI, etc.

- Edge: A computer system used to perform on-site computing tasks. The main role of "edge" was assumed by traditional industrial computers in the early days, or by general desktops and servers when the requirements were not so strict; now there is a trend of building embedded industrial computers with mid-to-high-end ARM architecture embedded systems

- Terminal: The device (secondary device) used to monitor and control the main device (primary device) in industrial applications, and the device (secondary device) to monitor various main devices in the Internet of Things environment. The main role of "end" was realized by low-end embedded single-chip microcomputer system in the early stage; at present, it is gradually transitioning to low-end embedded system (main frequency below 1GMHz) as the mainstream solution

From the above analysis, it is not difficult to see that the application of industrial computer is mainly located at the "edge" level. As a specific application of "edge", the embedded industrial computer mainly carries the following two types of functions:

- Automatic operations, such as gateways, NVRs, routers, firewalls, etc., are realized through specially designed industrial-grade low-end embedded computer systems. Some have simple character/bitmap-based display and special button parameter configuration and status display functions

- Interactive operation class, complete monitoring and system (including HMI human-computer interaction interface) and other functions, realized through a specially designed industrial-grade mid-to-high-end embedded computer system, with the interactive ability of vector graphics system

Typical Application Scenarios of Embedded Industrial Computers

- The edge "brain" of intelligent power distribution room, computer room power environment, pumping station, intelligent park, intelligent campus, intelligent manufacturing, etc., realizes the connection with on-site data acquisition unit, measurement and control device, protection equipment, PLC equipment, CNC equipment, and robot equipment Access, protocol analysis, alarm processing, conversion, integrated transmission and control

- Embedded SCADA system (C/S, B/S mode)

- 100ms level soft PLC

- Industrial control/IoT field small data server

- Enterprise workshop-level industrial kanban/OEE kanban, lightweight MES front-end data acquisition and display that meet the requirements of "intelligent transformation and digital transformation"

- Development and operation platform for third-party algorithms and models based on industry applications

- Access and push of video front-end equipment, video recording and linkage, video AI analysis interface and comprehensive linkage of analysis results

- On-site network security and audit

BPI-6202 Embedded Single Board Industrial Computer

BPI-6202 as a simple embedded general controller hardware and software development platform, it provides fully functional hardware solutions for application developers, and supports BSP+docker development environment. Provide strong edge computing support. Developers can quickly utilize the development platform, develop and productize

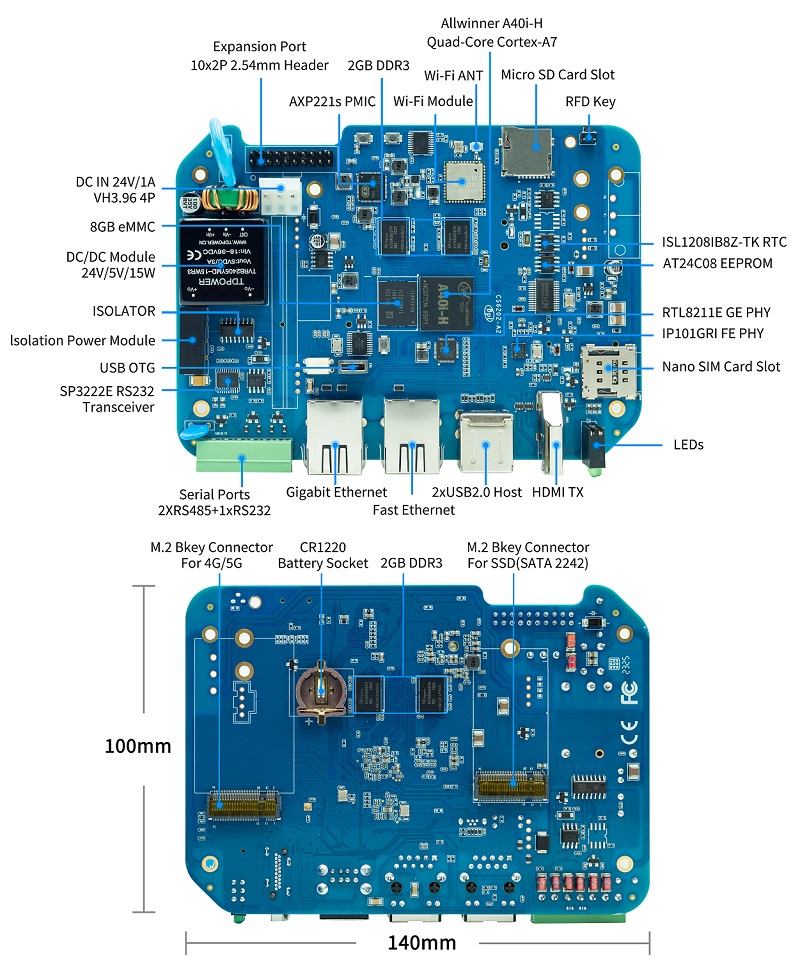

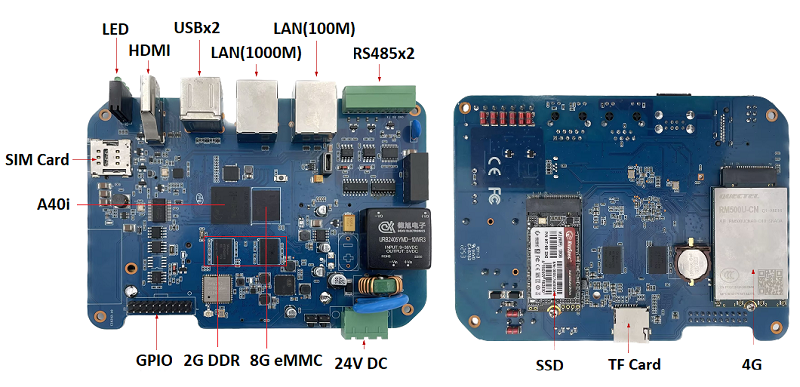

BPI-6202 PCBA design

PCBA interface

PCBA spec

| CPU and OS | Allwinner A40I ARM Cortex-A7 quad cord 1.2GHz,Ubuntu/Mate |

| Memory | 2GB DDR3,8GB EMMC ;support SSD hardisk |

| Storage | 8GB EMMC ;support SSD Hardisk |

| communication function | Ethernet port: 1 x 1000M + 1 x 100M, independent MAC, 2 x RS485 with isolation + 1 x RS232 Consoel with isolation, 4G/5G full Netcom + WiFi |

| Extended function module | Signal definition display |

| HDMI | HDMI1.4, support 1080p@60fps ; USB supports keyboard, mouse; or resistive/capacitive display interface |

| Power | DC:24V |

PCBA with SSD and 4G support

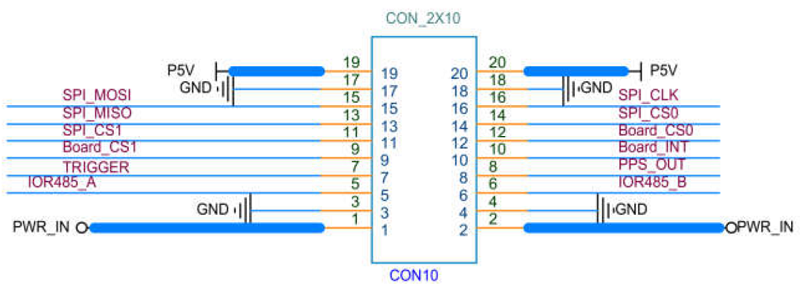

20 Pin GPIO expansion port

BPI-6202 also support expansion board ,The expansion port adopts 2.54mm pitch, 2x10P row pin seat, which is used to expand 10 interfaces.

The BPI-6202 supports modular design, provides rich expansion interfaces, and can use the basic unit + 5 expansion units to support on-demand configuration. Extended IO unit modules include:

- 7 x RS485 module with isolation

- 16 x DI module (switch input module), passive input (up to 5 modules can be mixed)

- 16 x DO module (switch output module), relay output (up to 5 modules can be mixed)

- 8 x DI+8 x DO O module (switch input/output module), relay output (up to 5 modules can be mixed)

- 8 x AI + 4 x AO module (analog input/output module), support 0-5V, 0-20mA input

- Customized Lora, ZigBee, 433M wireless transmission modules, power line carrier modules, and other functional modules,

- The function board can be customized by third parties and can communicate with BPI-6202

All boards are connected via internal bus(485 or SPI) in the box

Banana Pi BPI-6202 expansion gateway design

BPI-6202 product

About BPI-6202 Product

BPI-6202 is a cost-effective general-purpose embedded single-board industrial computer developed by Banana Pi community and Jiskaida Company for various industrial control fields. Compared with J1800/J1900 and other similar embedded products, it has the following advantages :

- Industrial-grade products, strong performance and low power consumption: industrial-grade standards, performance surpasses Celeron; low power consumption without heat dissipation, long-term operation

- Anti-interference design, suitable for harsh working conditions: power supply/network port/serial port are all designed according to EMC3~4 level

- Single-board structure, more reliable without plugging: integrate the functions of the core board and the bottom board, with higher reliability and longer life

- The integration of the industrial chain ensures high quality and low price. By optimizing the industrial chain links, the quality of mass production is guaranteed and the cost is extremely reduced.

- Innovative combination to meet different needs, open hardware information, single board/machine/industrial control software, optional

- Long life cycle, long-term stable supply, the original CPU factory promises to supply for 10 years, guaranteeing the maximum return on R&D investment

Because BPI-6202 has strong computing power and more resources, in addition to completing the above functions, it can also provide various data interfaces, providing an ideal computing environment and secondary development capabilities for more industry application optimization algorithms.

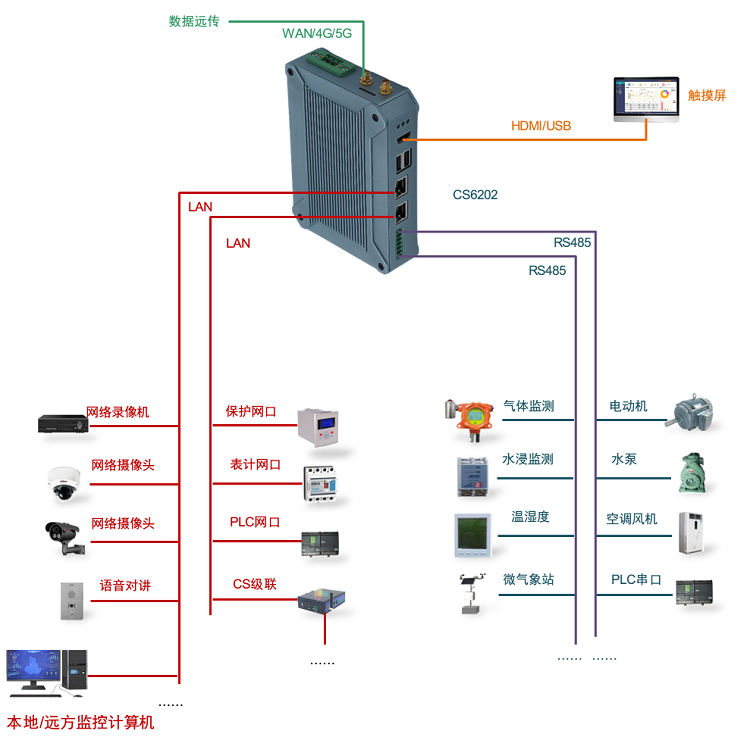

The appearance of the CS6202 including the chassis is shown in the figure below.

BPI-6202 interface description

| No | interface | illustrate |

| 1 | HDMI 1.4 | HDMI video cable to connect the video output port and the monitor. Note: The HDMI video cable is not included in the installation accessory package and needs to be purchased by the user. Please choose a shielded cable with a length less than 3M |

| 2 | USB 2.0 | Use the USB interface to connect the keyboard/mouse/touch screen, and connect the U disk. Note: The USB interface does not support hot swapping of storage devices. |

| 3 | Ethernet port | Use a network cable to connect the Ethernet port of the device to the switch, supporting 1 x 1000M + 1 x 100M |

| 4 | RS232/RS485 | Phoenix terminal, RS232 x 1+ RS485 x 2, connect the cable terminal to the Phoenix terminal interface of CS6202, and make sure that the peer device and BPI-6202 are connected to the ground wire. |

| 5 | DC power | Phoenix terminal, using 24V DC power supply |

| 6 | WiFi Antenna Mount | SMA-K (external thread + internal hole), if you need to use the antenna to connect to the network, connect the antenna device to the BPI-6202 through the antenna interface. Standard 1 antenna, Wifi antenna, 4G+WiFi; |

| 7 | 4G/5G Antenna Mount | A standard 4G antenna is provided. If you need to expand 5G, you need to use a customized chassis and configure 4 additional antennas |

| 8 | 3 indicator lights | From top to bottom, they are: system running light, which flashes regularly during normal operation; reserved light (programmable and controllable); 4G/5G running light, showing cellular communication status |

BPI-6202 product key feature

1,The industrial product and application development platform, BPI-6202 embedded single-board industrial computer, can play the following roles::

- Finished product of industrial control application: With its rich hardware resources (network, serial port, 4G/5G/WiFi, HDMI/USB display interaction, SSD hard disk) and application software (protocol gateway/video gateway, C/S+B/S mode SCADA, application publishing, PLC programming, gateway security and auditing functions), directly applied to the engineering site

- Basic platform for secondary development of industry applications: Provide development environment, interface and application environment based on Linux + Ngnix/HTTPS+ C/Python/Java/JS + MySQL/Sqlite/InfluxDB + Docker to meet the needs of various application developers

- Small data application server: provide edge computing/control nodes that are safe, reliable, cheap, and have sufficient computing power and storage capacity (large-capacity SSD hard disk)

- Open source project of hardware/operating system: provide complete hardware board-level open source to ecological partners, provide complete hardware information and basic operating system such as schematic diagram and PCB diagram of 6202 single-board industrial computer, and support users in 6202 single-board industrial computer On the basis of self-development of more single-board application systems

2,Industrial grade standard:

- Industrial-grade low-power fanless design, long-term stable operation on site

- Support -40℃~+70℃ wide temperature operation

- Implementation of GB/T17626, GB/T15153, IEC61850-3, EN61000-6-5 standards, EMC class III

3,Scalable function

- Support board expansion for customized enclosures, including electrical IO modules (AI/AO/DI/DO modules), extended serial port modules, extended Ethernet switching modules, HPLC communication modules, CAN communication modules, Zigbee communication modules, Lora communication modules, and Customized modules for other industry applications, using the internal high-speed bus to communicate with the 6202 main board

4,Data + video on-site integration

- 300+ international/national/industry/enterprise protocol libraries accumulated over the years, plug and connect, improve access efficiency, and analyze data accurately

- Video RTSP/RTMP, Onvif/GB28181 function, streaming media server function, H.264/H.265 playback function, data linkage short video linkage alarm recording function, camera AI analysis event capture/upload function (released recently), data OSD printing code function (released soon)

- Solve the long-term problems and pain points that video surveillance is independent of data surveillance and requires video manufacturers' front-end + back-end binding solutions

5,Lightweight PLC function (released recently)

- Through the IEC61131-3 programming language, PLC programming can be performed for all data in the gateway, and the lightweight PLC function can be realized through the electrical IO module

6,Multiple communication methods

- Support 2 independent IP network ports (1G+100M) * Support 2 RS485 serial ports + 1 RS232 Console

- Support WIFI, 4G/5G communication

- Scalable support CAN, ZigBee, Lora communication

7,HMIand upper computer function integration

- Connect the touch screen/large screen-keyboard-mouse through the HDMI/USB interface, and the application can realize friendly HMI interaction

- With the built-in full-featured SCADA system (C/S architecture and B/S architecture), it replaces the on-site X86+Windows architecture host computer system, suitable for unattended environments, and has a very high cost performance

8,Multi-core architecture, abundant resources, and sufficient computing power

- Allwinner A40i ARM Cortex-A7 Quad Core 1.2GHz + 2G DDR3 + 8G eMMC

- Support Built-in large-capacity SSD hard disk

- Abundant computing resources ensure more edge computing capabilities

- Built-in dongle encryption chip

- Built-in special encryption chip for national network communication

9,A variety of secondary development interfaces

- C, expression, ladder diagram, Java, Python, SqLite programming interface

- Docker function

Internal logical structure

External connection

Technical Description

BPI-6202 embedded single-board industrial computer, equipped with 2 independent MAC Ethernet ports (1G+100M), 2 RS485+1 RS232 ports, HDMI/USB, can be installed with large-capacity SDD hard disk, powerful and low price , Small size, easy guide rail installation, providing the most cost-effective on-site industrial control solution. As the master control node of edge computing, CS6202 makes full use of the powerful functions of embedded multi-core computing, which can access, process and display a large amount of on-site data; replace the conventional gateway + small monitoring system to achieve the optimal solution.

BPI-6202 is widely used in new energy, electric power, petroleum, rail transit, enterprise lightweight MES/industrial kanban, and IoT monitoring site automation application scenarios.

BPI-6202 has a built-in 300+ protocol interpretation library and real-time database, which can be connected to various protection devices, measurement and control devices, IEDs and other equipment at home and abroad, and supports IEC61850. Special protocols can be customized according to user requirements; an open API is provided to facilitate users to develop protocol software by themselves, and the protocol software can be downloaded independently.

BPI-6202 supports the access of hundreds of devices, data protocol analysis, conversion and unified transmission.

BPI-6202 has powerful video processing functions, supports RTSP/RTMP video push-pull streaming, Onvif/GB28181 protocol stack and other video surveillance transmission protocols, realizes compatible access to multi-manufacturer video front-end equipment (IPC, NVR), and configures large-capacity hard disk Later, it can replace NVR to realize video recording and playback functions. The unique linkage function based on data + video provides the industry's only solution for the perfect integration of data + video.

BPI-6202 supports complete C/S architecture SCADA system functions below 2048 points through HDMI display interface and USB keyboard and mouse (or touch screen); CS6202 provides B/S SCADA functions through Ngnix+Https, through C/S+ B/S mode hybrid configuration tool, flexible choice of C/S and B/S style

BPI-6202 supports the following configuration methods:

- Built-in WEB management, query/configure the working parameters of the device through the web page

- Dedicated configuration software to configure device parameters

- Cloud remote management, configure and diagnose the gateway through the cloud, and realize firmware and application upgrades

BPI-6202 uses the original iCoupler® digital isolation technology, RS485 automatic direction control, and RS485 zero-delay transmission technology. The equipment has strong adaptability and good compatibility, and can adapt to various harsh industrial sites and IoT sites, ensuring the reliability of communication and various IO semaphores.

Note:

- The power supply of BPI-6202 is DC24V

The main function

- 1) Built-in 300+ communication protocol library (see protocol list for details), including: MQTT and other IoT protocols, BACNET, OPC UA, IEC 60870-5-101/103/104, CDT, SPABUS, standard MODBUS and dozens One variant, plug and play; special protocols can be quickly customized according to needs, and a secondary development environment can be provided

- 2) Support various PLC connections such as Siemens/AB/Schneider/Mitsubishi

- 3) Support access to mainstream CNC equipment and mainstream robot equipment

- 4) Support IEC61850 Server/Client function, realize the two-way conversion between traditional protocol and 61850

- 5) Video stream acquisition, transmission, distribution, PTZ control, local streaming server functions

- 6) Encrypted transmission, breakpoint resume

- 7) Built-in RTC, providing high-precision time reference

- 8) 4G/5G/WIFI function

- 9) HDMI/USB interface, with the UI operation of the embedded SCADA system, can directly drive the kanban/big screen

- 10) Local device configuration management, cloud device configuration management

- 11) Telnet, SNMP service

- 12) Strong electromagnetic compatibility design, in line with relevant international standards, has good anti-interference ability

- 13) It can carry out secondary development, provide complete protocol development tools, various API interfaces, freely customize protocols, and deploy various industry application apps

- 14) Guide rail installation, beautiful appearance, convenient screen assembly

- 15) Full-featured SCADA function, including C/S mode and B/S mode

- 16) Container (Docker) function

- 17) Built-in network security module, support black and white list and protocol security control, audit, log function

Technical specifications

| CPU and OS | Allwinner A40I ARM Cortex-A7 quad cord 1.2GHz,Ubuntu/Mate |

| Memory | 2GB DDR3,8GB EMMC ;support SSD hardisk |

| Storage | 8GB EMMC ;support SSD Hardisk |

| communication function | Ethernet port: 1 x 1000M + 1 x 100M, independent MAC, 2 x RS485 with isolation + 1 x RS232 Consoel with isolation, 4G/5G full Netcom + WiFi |

| Extended function module | Horizontal expansion capability is reserved, and the expansion of various functional modules can be customized. The initial stage includes: RS485: with isolation; DI: passive input type, the module provides 24V isolated power supply; DO: relay output type, NC, COM, NO nodes; AI: 0-5V/4-20mA, 2-wire/3-wire input, the board provides 24V isolated power supply; AO: 0-5V/4-20mA, 2-wire/3-wire output, external 24V isolated power supply; AI + AO: 0-5V/4-20mA, 2-wire/3-wire input/output. The power supply is the same as above; other custom modules |

| HDMI | HDMI1.4, support 1080p@60fps ; USB supports keyboard, mouse; or resistive/capacitive display interface |

| Data processing capability | Equipment access capability: <=128 units (adjustable according to bandwidth and sampling period); analog value<10000; digital value<10000; control value<10000; expression calculation definition, alarm processing |

| video processing capability | Video RTSP/RTMP, Onvif, GB28181; video recording and playback; data trigger clip video recording and uploading; video AI event return and linkage, data OSD coding; local streaming service; H.264/H.265 playback |

| SCADA function | Full-featured SCADA system, processing points: 2048 points, C/S or B/S mode |

| development environment | Edge computing secondary development environment such as C/expression/ladder diagram/Java/Python |

| encryption chip | Software license authorization encryption chip (SMEC98SP); special encryption chip for State Grid communication (SC1161Y) |

| Power | DC:24V |

Environmental Specifications

| No | illustrate |

| Operating temperature | -40~+60℃ |

| Storage temperature | -40~+75℃ |

| Working humidity (RH) | 5%~95% non-condensing |

| Storage Humidity (RH) | 5%~95% non-condensing |

| Altitude | <5000m |

| lightning protection | Built-in lightning protection components, support outdoor use, meet high-level EMC standards |

| Degree of protection | IP40 |

| Cooling method | Natural heat dissipation without fan |

| Electromagnetic Compatibility | EMC class III, GB/T17626, GB/T15153, IEC61850-3, EN61000-6-5 |

| Safety | GB/T7621-2008 |

| certified | CE,FCC,RoHS |

Physical Specifications

| Size(WxDxH) | 36mm x105mm x 145mm,DIN-rail installation, the width of customized expansion is 30mm x n+6 (n≥2, the width of customized expansion) |

| Weight | 0.5kg |

| Power consumption | Typical power consumption: 5W, maximum power consumption: 10W |

Source code

BPI-CS6202 BSP source code: https://github.com/BPI-SINOVOIP/bpi-cs6202

Resource

- BPI-6202 Schematic

- Baidu Cloud: https://pan.baidu.com/s/1aKr_53jHmsH4bRMKxJU6Eg?pwd=8888 (pincode:8888)

- Google Drive: https://drive.google.com/file/d/1gxg68TW2lFCxtRckjYkzm53WFViIVDco/view?usp=sharing

System Image

- 2023-09-06 ubuntu-mate-20.04.1-desktop

- Baidu Cloud: https://pan.baidu.com/s/1CZblAEA9BwQyhpgALmQ4QA?pwd=8888 (pincode:8888)

- Google Drive:https://drive.google.com/file/d/1LPRya12Gl3QcctPN-ukCtiEWSSLjBXp8/view?usp=sharing

Cooperation method

- 1. BPI-6206 is an open-source hardware product. The Banana Pi community provides all BSP board-level support codes and supports Docker containers in the codes. Customers with technical development capabilities can directly carry out secondary application development on BPI-6202.

- 2. BPI-6202 as a basic platform for secondary development, it provides various development tools and protocol analysis database interfaces for application developers, greatly shortening the development week of various industry application products and reducing the difficulty of development.

- 3. BPI-6202 is a complete industrial control product, customers can directly use it for industrial control and provide complete product-level support.

Easy to buy sample

- BIPAI Aliexpress shop: https://www.aliexpress.us/item/3256805770014268.html?spm=5261

- SINOVOIP Aliexpress shop:https://www.aliexpress.us/item/3256805769921309.html?gatewayAdapt=glo2usa4itemAdapt

- Taobao Shop: https://item.taobao.com/item.htm?spm=a2126o.success.0.0.dc424831k8uXKd&id=734545159836

- OEM&ODM please contact : [email protected]