Difference between revisions of "基于BPI-M2 Ultra 的工业控制网关设计"

(→Overview) |

(→介绍) |

||

| Line 9: | Line 9: | ||

这是香蕉派[[BPI 4.0 定制服务]]案例,基于[[香蕉派 BPI-M2 Berry]]和[[香蕉派 BPI-M2U]]开发,采用 Allwinner A40i 工业级芯片设计。 | 这是香蕉派[[BPI 4.0 定制服务]]案例,基于[[香蕉派 BPI-M2 Berry]]和[[香蕉派 BPI-M2U]]开发,采用 Allwinner A40i 工业级芯片设计。 | ||

| − | + | 国内外首创的同时连接近百台现场电气/物联网设备/视频前端设备的大型智能网关,集协议转换、视频接入传输/控制、电气IO量采集控制、嵌入式SCADA系统四大功能为一体,与控制中心形成统一的数据/视频通道,具备边缘计算功能;彻底消除长期以来视频监控独立于数据监控之外,并被视频厂家昂贵的整体方案绑架的痼疾和痛点,能够取代现场X86+Windows架构的计算机监控计算机系统,具有最佳的性价比。 | |

| + | 丰富的协议库,即插即连,极大提高现场接入效率;工业级的品质,保证在现场长期稳定运行;体积小、安装方式多样,价格低廉,适用于大规模的分布式现场应用部署 | ||

[[File:Industrial_control_gateway_1.jpg]] | [[File:Industrial_control_gateway_1.jpg]] | ||

Revision as of 01:36, 8 April 2021

Contents

介绍

Banana Pi BPI-M2U Allwinner R40/V40/A40i

Successful case for BPI:4.0 OEM&ODM

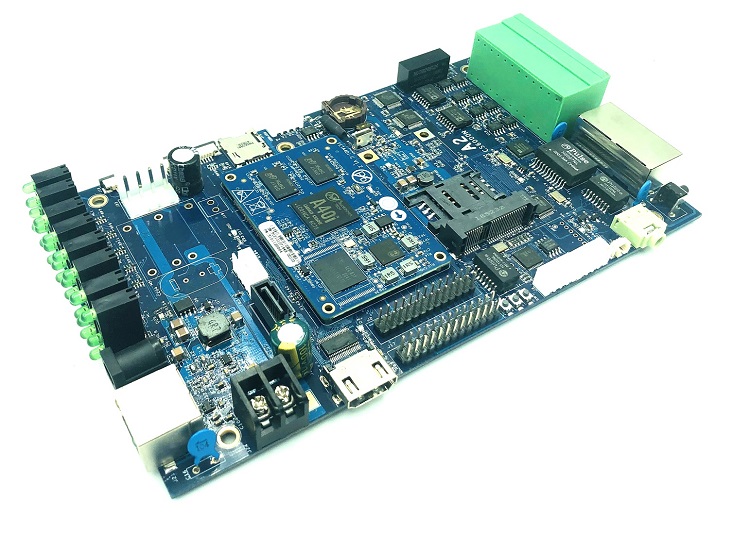

这是香蕉派BPI 4.0 定制服务案例,基于香蕉派 BPI-M2 Berry和香蕉派 BPI-M2U开发,采用 Allwinner A40i 工业级芯片设计。

国内外首创的同时连接近百台现场电气/物联网设备/视频前端设备的大型智能网关,集协议转换、视频接入传输/控制、电气IO量采集控制、嵌入式SCADA系统四大功能为一体,与控制中心形成统一的数据/视频通道,具备边缘计算功能;彻底消除长期以来视频监控独立于数据监控之外,并被视频厂家昂贵的整体方案绑架的痼疾和痛点,能够取代现场X86+Windows架构的计算机监控计算机系统,具有最佳的性价比。 丰富的协议库,即插即连,极大提高现场接入效率;工业级的品质,保证在现场长期稳定运行;体积小、安装方式多样,价格低廉,适用于大规模的分布式现场应用部署

The product features

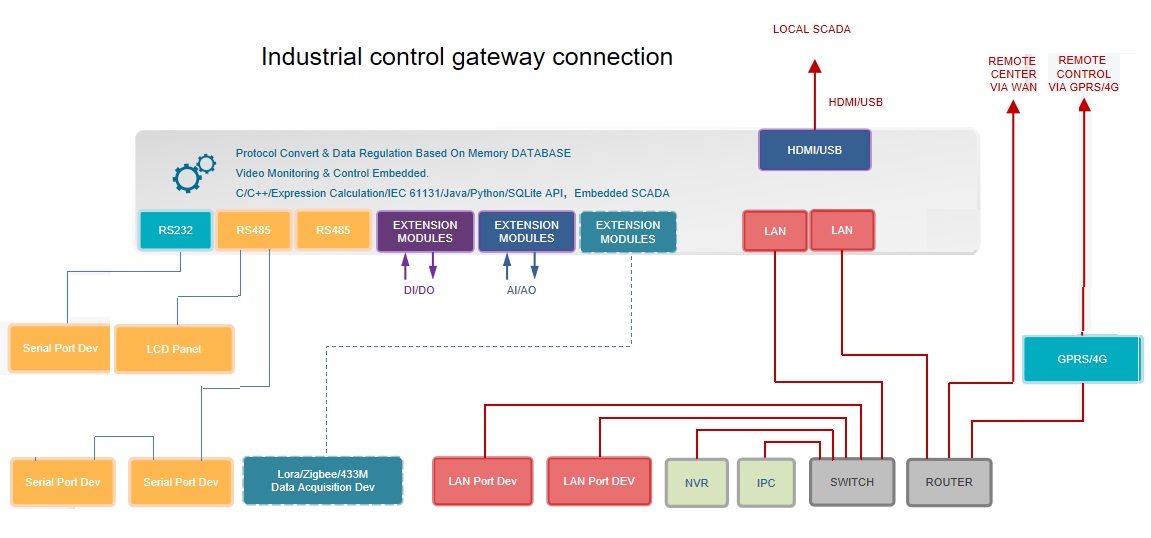

- Data protocol processing, video protocol processing, electrical IO quantity processing, embedded SCADA system "four in one" Protocol and edge calculation function secondary development ability, support C/ expression/ladder diagram /Java/Python application programming

- 1000+ sets of practical application cases, suitable for many industrial Ethernet, Internet of things application scenarios

- Embedded SCADA function, connected to the display screen or published through Web, replace the original X86+Windows conventional SCADA system function

Product introduction

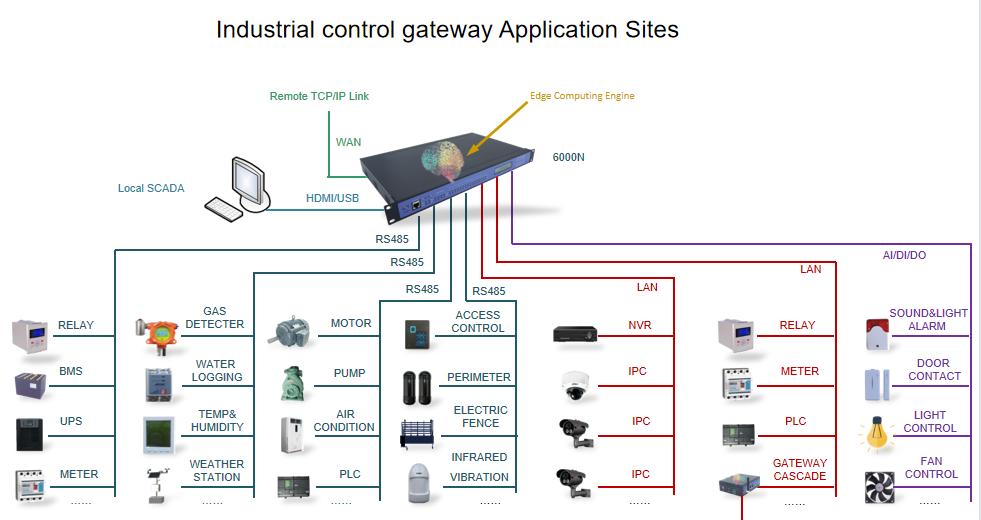

- this product have large industrial Internet of things intelligent gateway is a new generation of Internet of things access equipment, equipped with 2 independent IP Ethernet and 8 RS485 interface, flexible configuration, widely used in power, oil, factories and mines, and the Internet of things industry automation monitoring occasions.

- In order to meet the complex electrical and gas access requirements, CS6000N has designed three extensible IO slots. Each IO slot can be configured as any one of 8XRS485, 8XDI, 8XDO or 8XAI IO boards according to the needs, providing flexible configuration combinations.

- it has built-in massive protocol interpretation library and real-time database, can connect various domestic and foreign protection devices, measurement and control devices, IEDs and other equipment, and support IEC61850.Special specifications can be customized according to user requirements;Open API is provided to facilitate users to develop proprietary software, which can be downloaded independently.

- supports access of hundreds of devices, data protocol parsing, conversion and unified transmission.

- it has another big characteristic, is a powerful video processing capabilities, including RTSP/RTMP video of push-pull flow, Onvif/GB28181 protocol stack and other video surveillance transmission function, for many manufacturers video front-end equipment (IPC and NVR) compatible with access, equipped with large capacity hard disk can replace the NVR, video footage and playback function, provides the industry's only data fusion + video solutions.

- supports complete SCADA system functions under 5000 points through HDMI display interface and USB keyboard and mouse (or touch screen).

- supports three configurations:

- Built-in Web management, query/configure the working parameters of the device through the browser

- Dedicated configuration software configures device parameters

- Cloud remote management, configuration and diagnosis of gateways through gateways, firmware and application upgrade

- it's uses advanced Icoupler ® digital isolation technology, RS485 automatic direction control, RS485 zero delay transmission technology, fully consider the particularity of industrial field application in the design, follow EMI/EMC design specifications, adapt to a variety of harsh industrial field and the Internet of Things site, ensure communication and a variety of IO semaphoretic reliability.

Hardware

Hardware spec

| HardWare Specification | |||

| Performance | CPU: ARM Cortex -- A7 4-core, 1.2GHz, Linux,1GB/2GB DDR3, 8GB EMMC;Large capacity SD and large capacity hard disk can be built in | ||

| Basic communication unit | 100BASE-T Ethernet interface : 2-way;RS485: 8-way, with isolation | ||

| Expansion communication unit | number of slots: 3, combination mode: any combination,Type of board: 8XRS485:8-way 485, with isolation; 8XDI: Passive input type, board card provides 24V isolated power supply; 8XDO: Relay output type, NC, COM, NO node;8xAI: 0-5V or 4-20mA, 2-wire or 3-wire input, board card provides 24V isolated power supply | ||

| Display interface | HDMI1.4, support 1080P ,USB supports keyboard and mouse;Or resistive/capacitive display interface | ||

| Data processing function | Device access capacity: <=64 sets (adjustable according to bandwidth and sampling period);Analog quantity <10000;Digital quantity <10000;Control quantity <10000;expression calculation definition, alarm processing;Video RTSP/RTMP, ONVIF, GB28181, voice intercom;C/C++ expression/ladder diagram /Java/Python edge computing secondary development environment;Built-in SCADA software function, (SCADA processing points <2000 points);Docker feature (recently released) | ||

| Application environment | Operating temperature: -40℃~+80℃;Storage temperature: -40℃~+70℃,Relative humidity: less than 85%, no condensation; Working power supply: AC 85-265V, 50Hz;Power consumption: less than 20W | ||

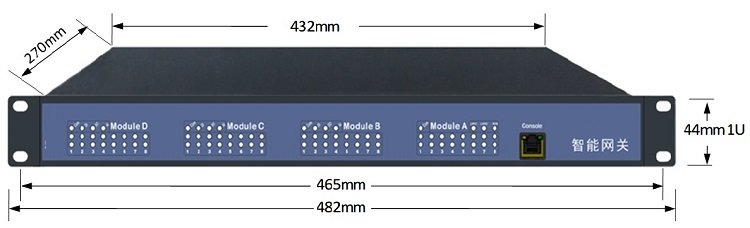

| Size and installation | 482mm×270mm×44mm (length × width × height); Rack type standard 19 inches 1U | ||

| Weight | Net weight: 2.5kg | ||

Hardware interface

Exterior industrial design

Software

Main function

- 1) Built-in 200+ communication protocol library (see protocol list for details), including: MQTT and other Internet of Things protocols, OPC UA, IEC 60870-5-101/103/104, CDT, SPABUS, standard Modbus and dozens of variants, plug and connect instantly;Special protocols can be customized quickly according to requirements, and secondary development environment can be provided

- 2) Support the whole series of Siemens PLC through industrial Ethernet communication;Support other types of PLC internal protocol communication

- 3) Support IEC61850 Server/Client function, realize the two-way conversion between the traditional protocol and 61850

- 4) Video stream acquisition, transmission, distribution, pan-head control, local streaming media server functions

- 5) Encryption transmission and breakpoint transmission

- 6) Built-in RTC to provide high precision time reference

- 7) Modular design, basic unit +3 extension units, support on demand configuration.The extended IO unit module includes:

- 8XRS485 module, with isolation

- 8XDI module (switch input module), passive input (support up to 3 modules mixed)

- 8XDO module (switch output module), 8 relay output (support up to 3 modules mixed)

- 8XAI module (analog input module), support 0-5V, 0-20mA input (support mixing of 3 modules at most)

- Rola, 433M wireless transmission module and power line carrier module can be customized according to requirements

- 8)HDMI/USB interface, with embedded SCADA system UI operation

- 9) Local device configuration management, cloud device configuration management

- 10)Telnet and SNMP services

- 11) Strong electromagnetic compatibility design, in line with relevant international standards, with good anti-interference ability

- 12) Can carry out secondary development, provide a complete protocol development package, can customize various protocols

- 13) Standard 19-inch 1U mounting type appearance, beautiful shape, convenient group screen

- 14) Embedded SCADA functionality

- 15) Docker functionality (coming soon)

Application Sites

Gateway connection

Open Source resource

this board base on BPI-M2 Ultra ,you can reference Banana Pi BPI-M2U

how to begin : Getting Started with M2 Ultra / Berry

Custom application

cooperative partner

- Hardware OEM&ODM please contact : [email protected]

- Total solution : https://www.aixiaocao.com/en/index.html