BPI-6202 Embedded single board industrial computer

Contents

Embedded industrial computer overview

Definition and application scenarios of embedded industrial computer

Industrial Personal Computer (IPC for short) is a reinforced and enhanced microcomputer that appeared in the 1990s and is widely used in industrial field monitoring and control. Industrial personal computers often operate in harsh environments. Data security requirements are also higher, so industrial computers are usually specially designed for reinforcement, dust-proof, moisture-proof, corrosion-proof, radiation-proof, etc. Up to now, the X86+Windows (Wintel) architecture is still the mainstream solution for industrial computers. It can be defined as a traditional industrial computer. Generally speaking

While the traditional industrial computer plays an important role in the automation and informatization of the industrial control field, its inherent weakness has always plagued manufacturers, integrators and users. Everyone is looking for a better solution

In the past ten years, the embedded system has developed rapidly. With its low power consumption, low cost and continuously improved high performance, it has become the only solution for mobile devices (mobile phones, PADs); The ideal choice for data acquisition and processing in various industries. The embedded system of ARM architecture has the characteristics of flexible and efficient customization of software and hardware solutions. At present, a complete industrial chain ecosystem has been formed, which can provide users with solutions that meet their actual needs and have certain advances. Products with extended margins and more competitive prices; when user needs gradually exceed the capabilities of current products, they can continuously provide new products that meet user requirements through rapid program design and iteration, and can realize "needs— —Technology—Scheme—Product—Market—User—Demand” a virtuous circle of rising

Compared with the traditional industrial computer, the specially designed system based on the embedded computer architecture is called the embedded industrial computer.

The main features of traditional industrial computer and embedded industrial computer are compared as follows:

| Nomber | Key elements | Traditional industrial computer (Windows+X86) | Embedded industrial computer (Linux+LoongArch/ARM) |

| 1 | performance | Commercial-grade Celeron or commercial/industrial-grade Core i3~I5 | Industrial grade, higher performance than Celeron, weaker than I3 |

| 2 | safety | Vulnerable, vulnerable to viruses and hackers | Stable system, few upgrades, high security |

| 3 | real-time | Poor real-time responsiveness | Real-time responsiveness can meet the requirements |

| 4 | reliability | High power consumption requires strong heat dissipation and low reliability | Low power consumption does not need to consider heat dissipation, high reliability |

| 5 | Scalability | It is complicated to expand various interfaces on the motherboard | It is more convenient to expand various interfaces on the core board/development board |

| 6 | industrial grade | It is more difficult to realize real industrial grade products | It is easier to realize real industrial grade products |

| 7 | Customization | Customization efficiency is low and cost is high | Application-oriented fast and efficient customization and iteration |

| 8 | performance | Insufficient or excess performance for industrial applications | Application-specific solutions with the best performance |

| 9 | overall price | higher | Application-specific, price advantage |

| 10 | Operation and maintenance cost | High power consumption and high operation and maintenance costs | Low power consumption and low cost, green and environmental protection |

| 11 | life cycle | Frequent replacement, difficult to guarantee inventory | Long CPU life cycle, guaranteed inventory |

Embedded industrial computer has become a strong competitor of traditional industrial computer. In the future, the former will form an overwhelming advantage over the latter, there is no suspense

Application Scenarios of Embedded Industrial Computers

The rapid development of the industrial Internet and the Internet of Things is not only a battle for many computer software and hardware manufacturers (including communication solutions and product manufacturers, which are essentially computer systems, even embedded system software and hardware manufacturers) trying to enter the relatively high-profit industry. It is a successive attempt to monitor the industry market; it is also an enlightenment movement to open up "people's awareness of people's wisdom" and popularize professional knowledge. This big storm, which has lasted for more than ten years, has expanded the general public's demand and imagination for monitoring and control applications to every corner of all walks of life

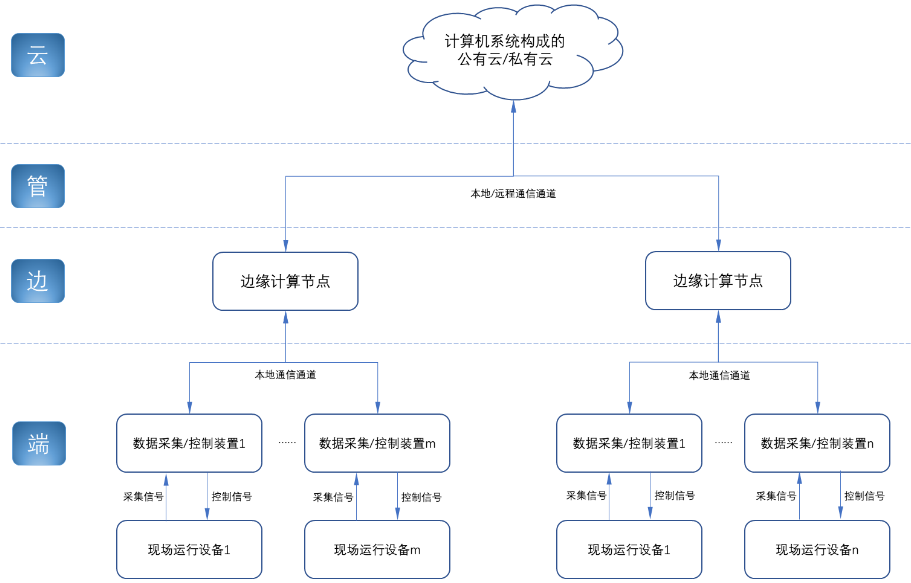

The concept of "cloud-pipe-edge-end" is a classic summary and induction of the principles of surveillance and control based on Internet thinking and terms; The mainstream model and architecture adopted by monitoring applications in various industries for decades

- Cloud: The computer system that implements the monitoring center system and more advanced application software and algorithms. The "cloud" here includes both the "public cloud" on the Internet and the "private cloud" on the enterprise LAN. Build "cloud" computer systems, currently mainly high-end X86+Windows/Linux servers, and their clusters

- Tube: Provide various efficient, reliable, convenient and cost-effective wired/wireless channels for both sides of the equipment. There are not only "pipes" between the "cloud" and "edge", such as wide area Ethernet, 4G/5G, etc.; between the "edge" and "end" of the application site, there are also pipes suitable for on-site application scenarios. The existence of wired/wireless "pipes", such as local Ethernet, serial port, high-speed power line carrier (HPLC), LoRa, ZigBee, WIFI, etc.

- Edge: A computer system used to perform on-site computing tasks. The main role of "edge" was assumed by traditional industrial computers in the early days, or by general desktops and servers when the requirements were not so strict; now there is a trend of building embedded industrial computers with mid-to-high-end ARM architecture embedded systems

- Terminal: The device (secondary device) used to monitor and control the main device (primary device) in industrial applications, and the device (secondary device) to monitor various main devices in the Internet of Things environment. The main role of "end" was realized by low-end embedded single-chip microcomputer system in the early stage; at present, it is gradually transitioning to low-end embedded system (main frequency below 1GMHz) as the mainstream solution

From the above analysis, it is not difficult to see that the application of industrial computer is mainly located at the "edge" level. As a specific application of "edge", the embedded industrial computer mainly carries the following two types of functions:

- Automatic operations, such as gateways, NVRs, routers, firewalls, etc., are realized through specially designed industrial-grade low-end embedded computer systems. Some have simple character/bitmap-based display and special button parameter configuration and status display functions

- Interactive operation class, complete monitoring and system (including HMI human-computer interaction interface) and other functions, realized through a specially designed industrial-grade mid-to-high-end embedded computer system, with the interactive ability of vector graphics system

Typical Application Scenarios of Embedded Industrial Computers

- The edge "brain" of intelligent power distribution room, computer room power environment, pumping station, intelligent park, intelligent campus, intelligent manufacturing, etc., realizes the connection with on-site data acquisition unit, measurement and control device, protection equipment, PLC equipment, CNC equipment, and robot equipment Access, protocol analysis, alarm processing, conversion, integrated transmission and control

- Embedded SCADA system (C/S, B/S mode)

- 100ms level soft PLC

- Industrial control/IoT field small data server

- Enterprise workshop-level industrial kanban/OEE kanban, lightweight MES front-end data acquisition and display that meet the requirements of "intelligent transformation and digital transformation"

- Development and operation platform for third-party algorithms and models based on industry applications

- Access and push of video front-end equipment, video recording and linkage, video AI analysis interface and comprehensive linkage of analysis results

- On-site network security and audit

BPI-6202 Embedded Single Board Industrial Computer

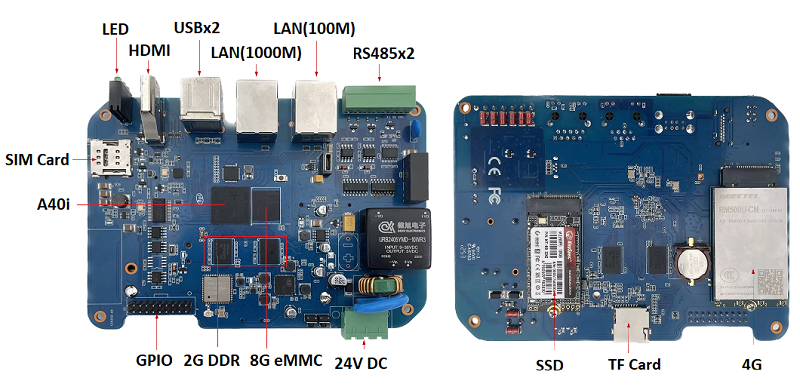

PCBA Hardware

product description

About BPI-6202 Product

BPI-6202,是Banana Pi社区与吉斯凯达公司面向各种工业控制领域需求研发的、高性价比的通用嵌入式单板工控机,对标J1800/J1900及其它同类嵌入式产品,具有如下优势:

- 工业级产品,性能强功耗低:工规级标准,性能超越赛扬;低功耗无散热,长期运行

- 抗干扰设计,适应恶劣工况:电源/网口/串口均按EMC3~4级设计

- 单板式结构,无接插更可靠:集核心板功能与底板功能一体,可靠性更高、寿命更长

- 产业链整合,确保质优价廉,通过优化产业链环节,保障量产品质,极致降低成本

- 创新性组合,满足不同需求,开放硬件资料、单板件/整机/工控软件,任意选择

- 长生命周期,长期稳定供货,CPU原厂承诺10年供货,保证研发投入的最大回报

由于BPI-6202具有较强的算力和较多的资源,,在完成上述功能外,还能够提供各种数据接口,为更多的行业应用优化算法提供理想的计算环境和二次开发能力。

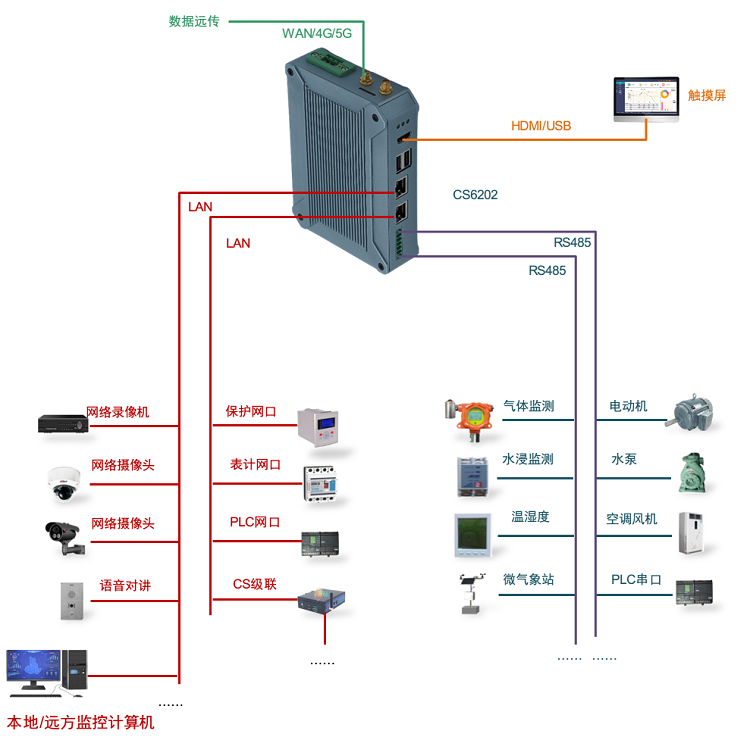

含机壳的CS6202外观如下图所示。

BPI-6202接口说明

| 序号 | 端口 | 说明 |

| 1 | HDMI 1.4接口 | 如需输出视频,使用HDMI视频线缆连接视频输出端口和显示器。说明:HDMI视频线缆不在安装附件包中,需要用户自行购买,请选择长度小于3M的屏蔽线 |

| 2 | USB接口 | 使用USB接口连接键盘/鼠标/触摸屏、以及连接U盘。说明:USB接口不支持存储设备热插拔。 |

| 3 | 以太网口 | 使用网线连接设备以太网口到交换机,支持1 x 1000M + 1 x 100M |

| 4 | RS232/RS485串口 | 凤凰端子,RS232 x 1+ RS485 x 2,将线缆端子与CS6202的凤凰端子接口相连接,并确保对端设备和BPI-6202都已经连接地线。 |

| 5 | 直流电源端子 | 凤凰端子,采用24V直流供电 |

| 6 | WiFi天线座 | SMA-K(外螺纹+内孔),如需使用天线连接网络,将天线设备通过天线接口连接至BPI-6202。标配1根天线,Wifi天线,4G+WiFi; |

| 7 | 4G/5G天线座 | 标配一根4G天线,如需扩展5G,需采用定制机箱并另外配置4根天线 |

| 8 | 3个指示灯 | 自上至下,分别为:系统运行灯,正常运行时定时闪烁;预留灯(编程可控);4G/5G运行灯,显示蜂窝通讯状态 |

主要特点

1,工业成品与应用开发平台,BPI-6202嵌入式单板工控机,可以扮演如下角色:

- 工控应用成品:以其所具有的丰富硬件资源(网络、串口、4G/5G/WiFi、HDMI/USB显示交互、SSD硬盘)和应用软件(协议网关/视频网关、C/S+B/S模式的SCADA、应用发布、PLC编程、网关安全及审计等功能),直接应用于工程现场

- 行业应用二次开发的基础平台:提供基于Linux + Ngnix/HTTPS+ C/Python/Java/JS + MySQL/Sqlite/InfluxDB + Docker的开发环境、接口及应用环境,满足各类应用开发者需要

- 小型数据应用服务器:提供安全可靠、价格低廉、具有充裕算力和存储能力(大容量SSD硬盘)的边缘计算/控制节点

- 硬件/操作系统的开源项目:向生态伙伴提供完全的硬件板卡级开源,提供6202单板工控机的原理图、PCB图等完整的硬件资料和基本操作系统,支持用户在6202单板工控机的基础上,自行开发更多的单板应用系统

2,工业级标准:

- 工业级低功耗无风扇设计,现场长期稳定运行

- 支持-40℃~+70℃宽温运行

- 执行GB/T17626、GB/T15153、IEC61850-3、EN61000-6-5标准,EMC III级

3,可扩展功能

- 支持定制外壳的板卡扩展,包括电气IO模块(AI / AO /DI /DO模块)、扩展串口模块、扩展以太网交换模块、HPLC通信模块、CAN通信模块、Zigbee通信模块、Lora通信模块,以及其他行业应用的定制模块,采用内部高速总线与6202主板通信

4,数据+视频现场整合

- 多年积累的300+国际/国家/行业/企业协议库,即插即连,提高接入效率,解析数据准确

- 视频RTSP/RTMP,Onvif/GB28181功能,流媒体服务器功能,H.264/H.265播放功能,数据联动短视频联动报警录像功能,摄像头AI分析事件捕获/上传功能(近期发布),数据OSD打码功能(近期发布)

- 解决长期以来视频监控独立于数据监控、需要视频厂家前端+后端绑定方案痼疾和痛点

5,轻量级PLC功能(近期发布)

- 通过IEC61131-3编程语言,可针对网关内所有数据进行PLC方式编程,通过电气IO模块,实现轻量级PLC功能

6,多种南向/北向通信方式

- 支持2个独立IP网口(1G+100M)*支持2路RS485串口+1路RS232 Console

- 支持WIFI、4G/5G通信

- 可扩展支持CAN、ZigBee、Lora通信

7,HMI及上位机功能集成

- 通过HDMI/USB接口连接触摸屏/大屏-键盘-鼠标,应用程序可实现友好的HMI交互

- 配合内置的全功能SCADA系统(C/S架构和B/S架构),取代现场X86+Windows架构的上位机计算机系统,适合无人值守环境,具有极高的性价比

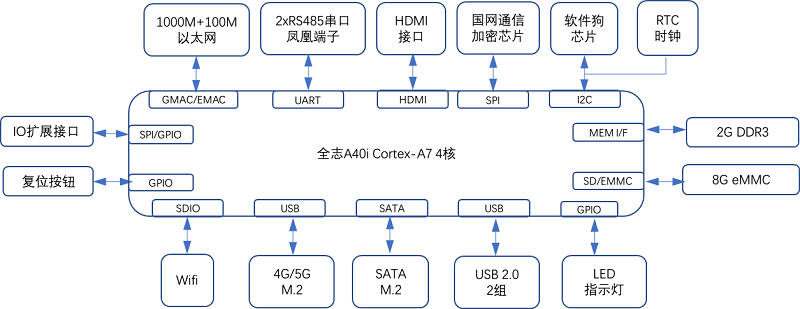

8,多核架构、资源丰富、算力充裕

- 全志A40i ARM Cortex-A7四核1.2GHz + 2G DDR3 + 8G eMMC

- 内置大容量SSD硬盘

- 丰富的计算资源,确保更多的边缘计算能力

- 内置软件狗加密芯片

- 内置国网通信专用加密芯片

9,多种二次开发接口

- C、表达式、梯形图、Java、Python、SqLite编程接口

- Docker功能

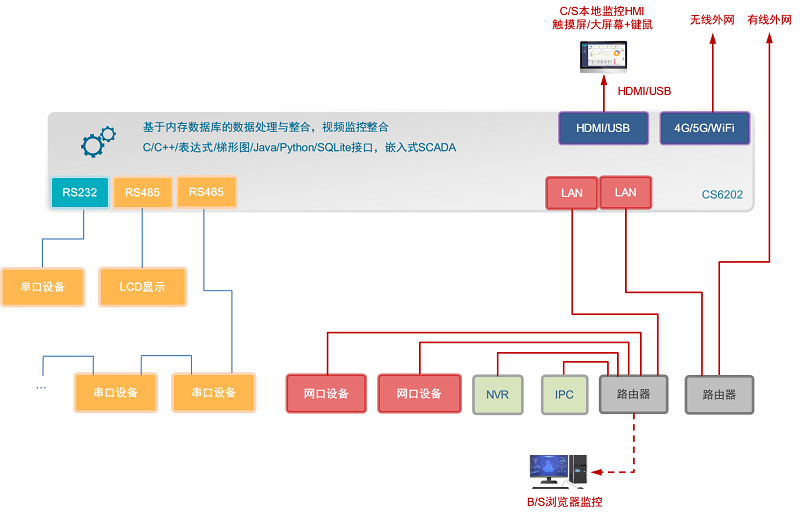

内部逻辑结构

外部连接方式

技术说明

BPI-6202嵌入式单板工控机,配置2个独立MAC以太网端口(1G+100M)、2个RS485+1个RS232端口、HDMI/USB,可加装大容量SDD硬盘,功能强大、价格低廉、尺寸小,导轨安装方便,提供最具性价比的现场工控解决方案。作为边缘计算的主控节点,BPI-6202充分利用了嵌入式多核计算的强劲功能,能够接入、处理并展示大量的现场数据;取代常规的网关+小型监控系统,实现最优的解决方案。

BPI-6202广泛适用于新能源、电力、石油、轨道交通、企业轻量级MES/工业看板、及物联网监控现场的自动化应用场景。

BPI-6202内置300+规约解释库和实时数据库,可连接国内外各种保护装置、测控装置、IEDs等设备,并支持IEC61850。可根据用户要求定制特殊规约;提供开放的API,方便用户自行开发规约软件,规约软件可独立下载。

BPI-6202支持数百台设备的接入,数据协议解析、转换与统一传输。

BPI-6202具有强大的视频处理功能,支持RTSP/RTMP视频推拉流、Onvif/GB28181协议栈等视频监控传输协议,实现对多厂家视频前端设备(IPC、NVR)的兼容接入,配置大容量硬盘后可取代NVR,实现视频录像及回放功能。独有的基于数据+视频的联动功能,提供了业界唯一的数据+视频完美融合的解决方案。

BPI-6202通过HDMI显示接口和USB键盘鼠标(或触摸屏),支持2048点以下完整的C/S架构SCADA系统功能;CS6202通过Ngnix+Https,提供B/S方式的SCADA功能,通过C/S+B/S模式的混合组态工具,可灵活选择C/S及B/S风格的

BPI-6202支持如下配置方式:

- 内置WEB管理,通过网页查询/配置设备的工作参数

- 专用的配置软件配置设备参数

- 云端远程管理,通过云端对网关进行配置和诊断,实现固件和应用程序的升级

BPI-6202使用了独创的iCoupler®数字隔离技术、RS485自动方向控制、RS485零延时传送技术,在设计上充分考虑了工业现场应用的特殊性,遵循EMI/EMC设计规范,对不同类型的RS485设备适应性强、兼容性好,能够适应各种严酷的工业现场和物联网现场,保障通信以及各种IO信号量的可靠。

注:

- BPI-6202的供电,为DC24V

主要功能

- 1)内置300+通讯规约库(详见协议列表清单),包括:MQTT及其它物联网协议、BACNET、OPC UA、IEC 60870-5-101/103/104、CDT、SPABUS、标准MODBUS及数十个变种,即插即通;可根据需求快速定制特殊协议,可提供二次开发环境

- 2)支持西门子/AB/施耐德/三菱等各类PLC连接

- 3)支持主流CNC设备接入、主流机器人设备接入

- 4)支持IEC61850 Server/Client功能,实现传统规约与61850的双向转换

- 5)视频流获取、传输、分发,云台控制、本地流媒体服务器功能

- 6)加密传输、断点续传

- 7)内置RTC,提供高精度时间参考

- 8)4G/5G/WIFI功能

- 9)HDMI/USB接口,配合嵌入式SCADA系统的UI操作,可直接驱动看板/大屏

- 10)本地设备配置管理,云端设备配置管理

- 11)Telnet、SNMP服务

- 12)强电磁兼容性设计,符合国际相关标准,具有良好的抗干扰能力

- 13)可进行二次开发,提供完整的协议开发工具、各种API接口,可自由定制协议、部署各种行业应用app

- 14)导轨式安装,造型美观,组屏方便

- 15)全功能SCADA功能,包括C/S模式和B/S模式

- 16)容器(Docker)功能

- 17)内置网络安全模块,支持黑白名单及协议安全控制、审计、日志功能

技术规格

| 处理器及OS | 全志A40I ARM Cortex-A7 四核1.2GHz,Ubuntu/Mate |

| 内存 | 2GB DDR3,8GB EMMC ;可配大容量SSD硬盘 |

| 基本通信功能 | 以太网口:1 x 1000M + 1 x 100M,独立MAC,2 x RS485,带隔离 + 1 x RS232 Consoel带隔离,4G/5G全网通+WiFi |

| 扩展功能模块 | 预留横向扩展能力,可定制各种功能模块的扩展,先期包括:RS485:带隔离;DI:无源输入型,模块提供24V隔离电源;DO:继电器输出型,NC、COM、NO节点;AI:0-5V/4-20mA,2线/3线输入,板卡提供24V隔离电源;AO:0-5V/4-20mA,2线/3线输出,外部提供24V隔离电源;AI + AO:0-5V/4-20mA,2线/3线输入/出。电源同上;其它定制模块 |

| HMI接口 | HDMI1.4,支持1080p@60fps;USB支持键盘、鼠标;或电阻/电容显示屏接口 |

| 数据处理能力 | 设备接入能力:<=128台(根据带宽和采样周期可调);模拟量<10000;数字量<10000;控制量<10000;表达式计算定义、报警处理 |

| 视频处理能力 | 视频RTSP/RTMP、Onvif、GB28181;视频录像、回放;数据触发片段视频录像、上传;视频AI事件回传并联动、数据OSD打码;本地流媒体服务;H.264/H.265播放 |

| SCADA功能 | 全功能SCADA系统,处理点数:2048点,C/S或B/S模式 |

| 开发环境 | C/表达式/梯形图/Java/Python等边缘计算二次开发环境 |

| 加密芯片 | 软件许可证授权加密芯片(SMEC98SP);国网通信专用加密芯片(SC1161Y) |

| 电源 | DC:24V |

环境规格

| 项目 | 说明 |

| 工作温度 | -40~+60℃ |

| 存储温度 | -40~+75℃ |

| 工作湿度(RH) | 5%~95%无冷凝 |

| 存储湿度(RH) | 5%~95%无冷凝 |

| 海拔高度 | <5000m |

| 防雷 | 内置防雷元件,支持户外使用,符合高等级EMC标准 |

| 防护等级 | IP40 |

| 散热方式 | 无风扇自然散热 |

| 电磁兼容 | EMC III级,GB/T17626、GB/T15153、IEC61850-3、EN61000-6-5 |

| 安规 | GB/T7621-2008 |

| 认证 | CE认证 |

物理规格

| 尺寸(宽x深x高) | 36mm x105mm x 145mm,导轨式安装,定制扩展的宽度为30mm x n+6(n≥2,为定制扩展时的宽度) |

| 重量 | 0.5kg |

| 功耗 | 典型功耗:5W ,最大功耗:10W |